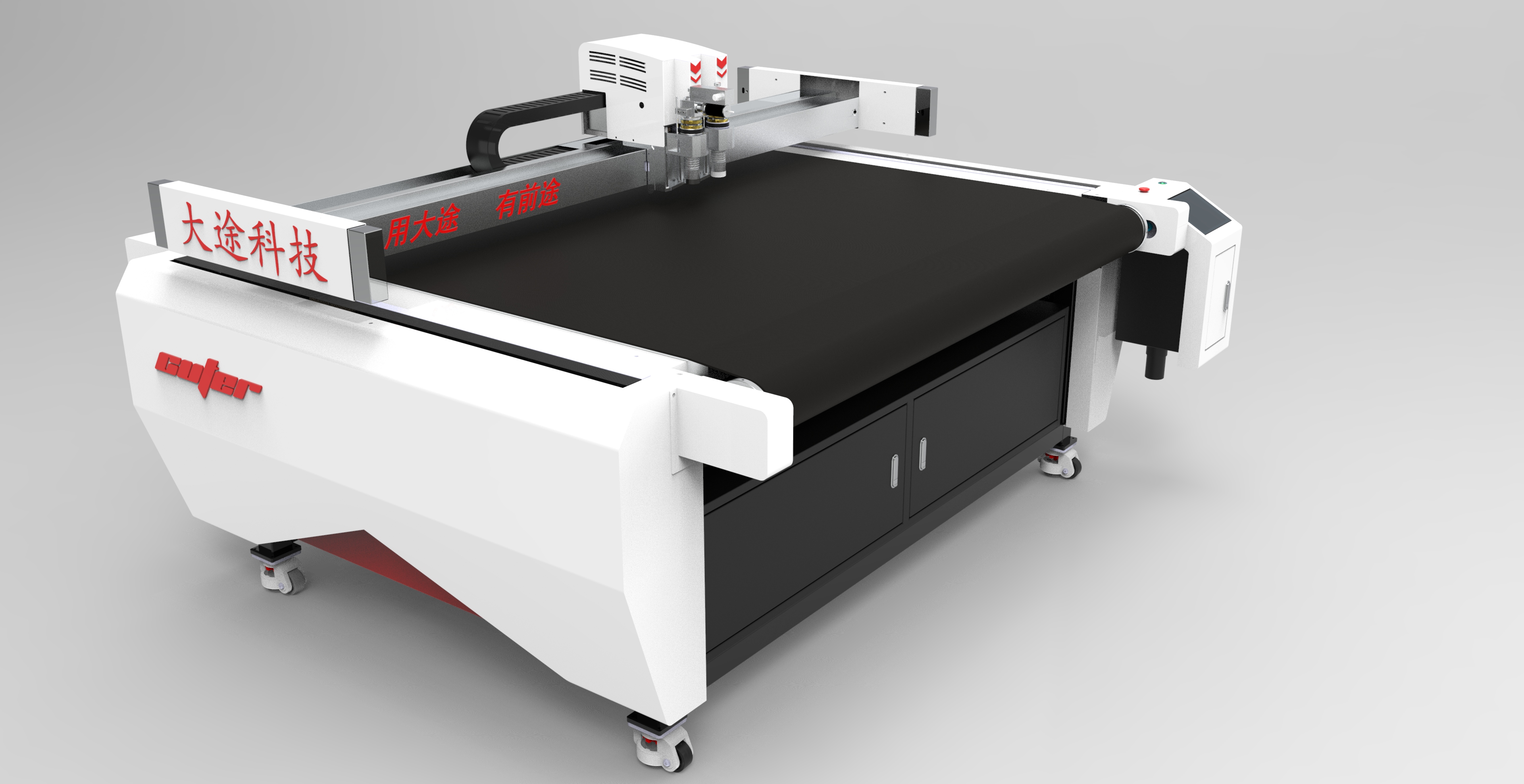

Izisetshenziswa ezifanele ukusika isampula yezingubo.Amasampula ezingubo asetshenziselwa imiphumela yokubonisa isampula.Amafomu okucubungula ahlukene futhi akhiqizwa amaqoqo amancane.Uma kusetshenziswa imishini yokusika enezingqimba eziningi, izindleko zokukhiqiza zizoba phezulu kakhulu.Uma kusetshenziswa ukusika ngesandla, futhi ngaphandle uma inekhono elikhethekile lokusika ngesandla, ayikho indlela yokuqinisekisa umphumela wokusika.Umshini wokusika uhlangabezana nezidingo zokusika isampula yezingubo.

Iumshini wokusika isampula yezinguboilawulwa yikhompyutha, futhi idatha ingeniswa emshinini wokusika.Umphumela wokusika uqinisekisiwe, futhi ukusebenza kahle kokusika kuphakeme kunaleyo yokusika ngesandla.Izindleko zomshini ziphansi kakhulu kunezomshini wokusika izingqimba eziningi. Bayanda abakhiqizi bezingubo abasebenzisa imishini yokusika isampula yezingubo.

Izinyathelo zokusika isampula yezingubo zomshini wokusika:

Inqubo yokusebenza yomshini wokusika isampula yezingubo ilula.Isinyathelo sokuqala ukufaka imidwebo yezingubo eziklanyelwe kukhompyutha, qala umsebenzi wokuhlela ngokuzenzakalelayo, ubeke izinto ezisetshenziswayo endaweni yokuphakela, qala ukusika ukhiye owodwa, bese okokusebenza kuyaqala. ukulayisha ngokuzenzakalelayo, ukusika ngokuzenzakalela, kanye nokuzikhulula ngokuzenzekelayo, uma izingcezu zengubo ziyinkimbinkimbi kakhulu, idivayisi iphinde isekele umsebenzi wokumaka othomathikhi.

Izinzuzo zomshini wokusika isampula yezingubo:

1. Ukusebenza kulula, kanti okokusebenza kunohlelo lokusika lwe-Datu oluzithuthukisile.

2. Umphumela omuhle wokusika nokunemba okuphezulu.Imishini isebenzisa i-Mitsubishi servo motor, ene-pulse positioning, ukunemba kokuma ±0.01mm, ukusika ngaphandle kwezinyo lesaha kanye ne-burr.

3. Londoloza okokusebenza, okokusebenza kusebenzisa isistimu yokubhala ehlakaniphile, engagcina ngaphezu kuka-15% wezinto zokwakha uma kuqhathaniswa nokuhlelwa kokuhlelwa ngesandla.

Isikhathi sokuthumela: Jan-03-2023