Umshini wokusika ikhompyutha owaziwa nangokuthi iumshini wokusika ummese odlidlizayo, ubude bemishini bungaba ngu-3100mm, ububanzi bungaba ngu-2100mm, indawo yebhentshi yokusebenzela ingu-1600mm * 2500mm, yiqiniso, indawo yebhentshi ukusekela ukwenza ngokwezifiso, umshini wokusika ikhompiyutha ngokuvamile usebenzisa uhlelo lokumisa i-pulse, ukuma. ukunemba ngokuvamile ±0.01mm.

Ngizokutshela izici ezithinta ukunemba komshini wokusika ikhompyutha kusuka ezicini ezine.

Into yokuqala ethinta ukunemba ukunemba kokubeka umshayeli, okubuye kube isisekelo sokunemba kokusika, uma kungekho isimo esinjalo, imishini ayilungile, futhi idrayivu evamile kanye nemoto ikhetha iMitsubishi.

Umthelela wesibili wephutha lomshini wokusika ikhompiyutha ukunwebeka kwempahla, indwangu, ukunwebeka kwesigaba soboya bekulingisa kukhulu, izinto ezinjalo noma imishini ilungiswa ibe yisimo esihle kakhulu, futhi iqale uhlelo lokunxeshezelwa kwephutha okuzenzakalelayo kwemishini, yayo. ukunemba ukusika cishe 5mm. Uma i-ductility yezinto ezifana nezinto zefilimu ye-elekthronikhi impofu, iphutha lokusika lomshini wokusika ikhompiyutha lingaba phakathi kuka-± 0.05mm.

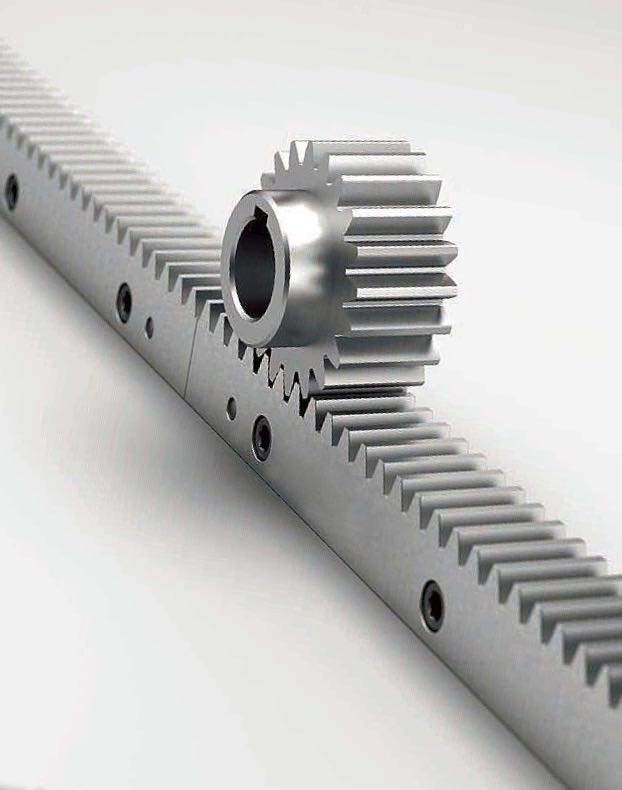

Okwesithathu, ukunemba kwesitimela somhlahlandlela wemishini kuthinta ngokuqondile ukunemba kokusika kwezinto, futhi ukulingana kwegiya lokuqondisa kuyisici esibalulekile esithinta ukunemba kwezinto ezibonakalayo, futhi i-helical gear kufanele isetshenziselwe ukunciphisa igebe phakathi.

Ukuqina kwemishini yesine, ukulungiswa kwemishini nakho kuyisici esibalulekile sokunemba kwemishini yokusika, abakhiqizi abaningi abanaki ukumiswa kwemishini kanye nezesekeli, umphumela wokunemba kokukhiqizwa kwemishini mubi kakhulu, singabeka ukumisa kwemishini ngaleso sikhathi. yokukhiqiza imishini, ukuze ukukhiqizwa kwemishini kubumbene.

Isikhathi sokuthumela: Nov-28-2023